Universal Laser Systems maximaliseert de materiaalcompatibiliteit in het nieuwe ULTRA 9-platform

Nieuw laserplatform maakt geavanceerde materiaalbewerking mogelijk

SCOTTTSDALE, Ariz.-(BUSINESS WIRE)- Met het toenemende gebruik van geavanceerde materialen in industriële toepassingen, van lucht- en ruimtevaart tot medische apparatuur, ontstaat er een groeiende behoefte aan innovatie in de technologie voor materiaalomzetting. Ontwikkelingen in de laserbewerking zijn erop gericht om de beperkingen van bestaande technologie te overwinnen en de grenzen te verleggen van de manier waarop materialen kunnen worden gebruikt. Universal Laser Systems heeft hiervoor een platform met ongekende mogelijkheden voor materiaalverwerking ontwikkeld.

Het nieuwe ULTRA 9 Platform is ontworpen om lasersnijden, laser ablatie en laser oppervlakte modificatie uit te voeren. Wanneer geconfigureerd met de gepatenteerde MultiWave Hybrid™-technologie, kan het de laserenergie van maximaal drie golflengtes – 9,3 µm (CO2), 10,6 µm (CO2) en 1,06 µm (vezels) – combineren door elke spectrale component van de straal onafhankelijk te besturen.

Universal Laser Systems Maximizes Material Compatibility in New ULTRA 9 Platform

New laser platform enables advanced material processing

SCOTTSDALE, Ariz.–(BUSINESS WIRE)– With the increasing use of advanced materials in industrial applications from aerospace to medical devices comes a growing need for innovation in material conversion technology. Developments in laser processing aim to overcome the limitations of existing technology and push the boundaries of how materials can be used. To this end, Universal Laser Systems has released a platform with unprecedented material processing capabilities.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20190221005340/en/

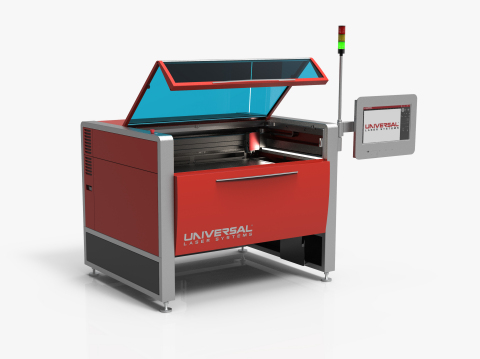

ULTRA 9 laser platform (Photo: Business Wire)

The new ULTRA 9 Platform is designed to perform laser cutting, laser ablation, and laser surface modification. When configured with patented MultiWave Hybrid™ technology, it can combine the laser energy of up to three wavelengths – 9.3 µm (CO2), 10.6 µm (CO2), and 1.06 µm (fiber) – by independently controlling each spectral component of the beam. The user is able to select the ideal wavelength or combination of wavelengths based on the material, allowing for maximum process flexibility.

MultiWave™ is just one of the features that makes the ULTRA 9 a comprehensive processing solution. Advanced functionality such as high-accuracy beam positioning and auto-focus, collision detection, and smart path planning, make it ideal for applications in manufacturing, research and development, academic research, and prototyping. Due to its versatility, the platform is effective for the broadest possible range of materials, including films, industrial fabrics, engineering plastics, laminating adhesives, foams, and composites from global manufacturers such as 3M, DuPont, Henkel, Rogers, SABIC, and Saint-Gobain.

To learn more about the ULTRA 9 Platform, visit https://www.ulsinc.com/products/platforms/ultra-9.

About Universal Laser Systems, Inc.

Universal Laser Systems, Inc. (ULS) is a global manufacturer of laser material processing solutions committed to advancing applied CO2 and fiber laser technology. Through the development of laser sources, software, and beam delivery systems, as well as extensive research in laser material processing, ULS provides its customers with innovative, cost-effective, and flexible laser solutions for present and future needs. For more information, visit www.ulsinc.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20190221005340/en/

Contacts

Thea Sander

480-483-1214 x211

tsander@ulsinc.com