CORRECTIE EN VERVANGING: Konica Minolta: Zeer snelle en scherpe textielprinter met één enkele printgang Nassenger SP-1 debuteert eind 2015

Het onderstaande bericht vervangt het persbericht van 11 augustus 2015

– Konica Minolta demonstreert in september zijn nieuwe technologie in Italië en stelt deze in november tentoon op ITMA 2015 in-

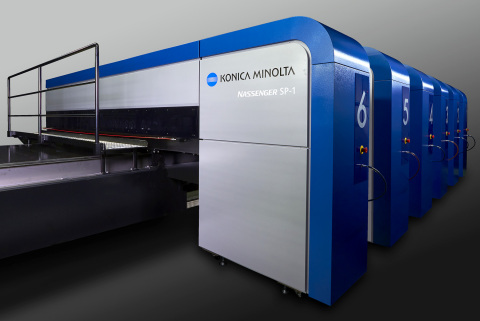

TOKYO–(BUSINESS WIRE)– Konica Minolta, Inc. introduceert in het najaar van 2015 zijn Nassenger SP-1, een zeer productieve inkjetprinter met een enkele printgang voor afdrukken met hoge resolutie op textiel. Het bedrijf speelt met de introductie van de nieuwe textielprinter in op het toegenomen gebruik van digitale prints in de sector voor textieldrukken. Voorafgaand aan de lancering demonstreert Konica Minolta de Nassenger SP-1 in september bij zijn dochteronderneming in Italië. Vervolgens onthult het bedrijf de technologie van het printermodel op ITMA 2015, een internationale expo van textielwerktuigen die in november 2015 in Milaan plaatsvindt.

De Nassenger SP-1 wordt gekenmerkt door geavanceerde functies, zoals de ultrahoge printsnelheid, grote productiecapaciteit en hoge resolutie, die mogelijk zijn gemaakt door Konica Minolta’s expertise in de ontwikkeling en productie van printkoppen, printermechanismen en inktsoorten voor inkjetprinters voor textiel.

CORRECTING and REPLACING Konica Minolta: Nassenger SP-1, an Ultra-High-Speed Inkjet Textile Printer Using a Single Pass System, to Be Launched at the End of 2015

TOKYO–(BUSINESS WIRE)– Please replace the release dated August 11, 2015, with the following corrected version due to multiple revisions.

This Smart News Release features multimedia. View the full release here:http://www.businesswire.com/news/home/20150811005475/en/

Nassenger SP-1 Inkjet textile printer (Photo: Business Wire)

Nassenger SP-1 Inkjet textile printer (Photo: Business Wire)The corrected release reads:

KONICA MINOLTA: NASSENGER SP-1, AN ULTRA-HIGH-SPEED INKJET TEXTILE PRINTER USING A SINGLE PASS SYSTEM, TO BE LAUNCHED AT THE END OF 2015

– Konica Minolta starting demonstrations in Italy in September, and showcasing the technology at an international exhibition, ITMA 2015, in November –

Konica Minolta, Inc. (Konica Minolta) (TOKYO:4902) (ISIN:JP3300600008) will launch at the end of 2015 the Nassenger SP-1, a high-productivity, high-resolution inkjet textile printer that employs a single pass system, in response to the increasing use of digital printing in the textile printing industry. Prior to the launch of this new model, Konica Minolta will give demonstrations of Nassenger SP-1 to customers at its sales subsidiary in Italy, starting from September 2015, and then showcase this model’s technology at ITMA 2015, an international textile machinery exhibition held in Milan, Italy in November 2015.

Nassenger SP-1 is characterized by advanced features such as ultra-high speed, high productivity and high resolution, which are made possible by Konica Minolta’s expertise in developing and producing all printheads, printing mechanisms and inks for inkjet textile printers.

Main features

- Nassenger SP-1 employs a single pass system that prints on a fabric (or other print medium) as the fabric is fed under a fixed print unit. This model boasts a much higher print speed than a scan-type printer that prints by moving a printhead carriage back and forth, and thus can meet the needs of the market for a printer with the speed of a screen printing machine.

- The highly precise ink ejection control capability of this model enables high-resolution images to be reproduced at an ultra-high speed.

- The model incorporates a newly developed printheads that can eject smaller ink droplets than conventional printers and Konica Minolta’s proprietary ink ejection control technology, which enables the ink droplet size to be adjusted (large, medium, and small), thus achieving higher-quality reproduction of fine patterns and color gradients.

- The model employs the following mechanisms that help to reduce downtime that can directly affect productivity:

– Konica Minolta’s proprietary image processing technology minimizes the problems of streaking and uneven density on a printed image and reduces defective prints.

– The modular printhead and the capability of automatic adjustment of ink droplet ejection positions enable far faster exchanging of printheads. - Reactive dye ink *1 and disperse ink *2 developed specifically for the single-pass system can be used. The reactive ink meets the criteria of the Global Organic Textile Standard (GOTS) *3.

Background to the development

In the global textile market, there have been increasing demands for low-volume high-mix production, shorter lead time, improved print quality, resource saving and environmental preservation. Against this backdrop, inkjet textile printing is gaining popularity among customers for the unique capabilities of digital printing that can cater to all these demands, namely: (1) on-demand printing, (2) plateless printing, and (3) greater environment friendliness resulting from the reduction of effluent and use of fuels.

While screen printing machines with print speeds of 2000-3000 m 2/hour are used for high-volume printing in most cases, users of these machines are now calling for inkjet textile printers with the print speed of screen printing machines. Nassenger SP-1 was developed to meet the needs of these users.

*Demonstration of Nassenger SP-1

Konica Minolta will set up a demonstration room in Konica Minolta IJ Textile Europe, a sales subsidiary established in Como, Milan, the center of the textile printing industry in Europe, to give demonstrations of Nassenger SP-1 for prospective customers starting from September 2015.

*ITMA 2015

ITMA is the largest textile machinery exhibition in the world, held every four years. ITMA 2015 will be held from November 12 to 19 in Fiera Milan (Rho), where Konica Minolta will showcase the technology of Nassenger SP-1 at its booth C108 in Hall 18.

*1: This ink is most suitable for fabrics made of plant fibers such as cotton and rayon.

*2: This ink is most suitable for fabrics made of artificial fibers such as polyester.

*3: GOTS is a global standard for textiles made from organic fibers, and regulates the chemicals used throughout the production process from raw cotton to finished products. The GOTS certification is given to products and dyes that meet comprehensive criteria, both environmental and social, set by GOTS.

For more information,

http://www.konicaminolta.com/inkjet/

View source version on businesswire.com:http://www.businesswire.com/news/home/20150811005475/en/

Contacts

Konica Minolta, Inc.

Akihisa Maruyama, +81-42-589-3702

Inkjet Business Unit

textile-support@pub.konicamin olta.jp

http://www.konicaminolta.com/inkjet/